Chemical Composition

| C % | Si≤% | Mn≤% | P≤% | S≤% | Ni≤% | Cr % | |

| 42D002 | 0.65-0.70 | 0.80 | 1.00 | 0.035 | 0.005 | 0.30 | 13.00-14.00 |

| ··· | ··· | ··· | ··· | ··· | ··· | ··· | ··· |

Mechanical Properties of Precision Stainless Steel Cold-Rolled Strips

| Tensile Strength | Yield Strength | Elongation | Hardness | ||

| Min (Mpa) | Min (Mpa) | Min% 50mm | HRB | HV | |

| Stainless Steel Cold-Rolled Strips | 540 | 660 | 3 | Min 92 | 200-320 |

Features of Our Razor Blade Steel

◆ Carefully designed microstructure

◆ Strict dimensional tolerance control

◆ Free from harmful non-metallic inclusions

◆ Excellent grinding, hardening, and honing performance

◆ Smooth, burr-free cutting edges

◆ Customized to requirements

Applications

disposable razors

Electric shaver

disposable scalpels

medical instrumen

Supply Form

For razor blade steel, DSM provides precision stainless steel cold-rolled strips in coil form.

| Thickness | Thickness Tolerance | Width | Width Tolerance | ||

| (mm) | (inches) | (mm) | (mm) | (inches) | (mm) |

| 0.075-0.10 | 0.003-0.004 | Min ±0.003mm | 1.2-700 | 0.047-27.560 | Min ±0.003mm |

| 0.120-0.50 | 0.005-0.020 | Max ±0.005mm | Max ±0.10mm | ||

Precision stainless steel cold-rolled strips are wound on plastic reels with an inner diameter of 280 mm (11.024 inches). The maximum outer diameter of the steel strip reel is 870 mm (34.252 inches). This means that a single strip with a width of 22.1-22.4 mm (0.870-0.882 inches) can have a maximum weight of approximately 91-93 kg.

(Note: Delivery sizes and special dimension requirements can be customized as per request.)

To meet various customer needs, we offer a range of surface finishes, including 2B matte, 2B surface, and 2B bright. The surface roughness (Ra) ranges from 0.04 to 0.08 µm.

The edges of the steel strips are trimmed with burr heights of 0.001-0.002 mm. For special edge requirements, additional edge grinding treatments can be provided.

Packaging

DSM uses various packaging standards to ensure that products are neatly and attractively packaged. The packaging provides protection against rust, moisture, dust, pressure, impact, and scratches, ensuring that the materials arrive at the customer's warehouse in perfect condition. Small wooden blocks are placed between the strips to facilitate easy handling.

Each steel strip is labeled with relevant material information, including coil number, steel grade, dimensions, and net weight. Additionally, a main sample is included with each bundle to facilitate customer inspection and testing.

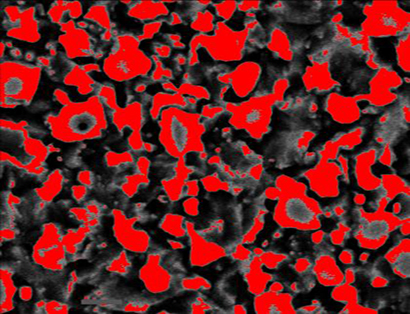

Microstructure

The size and quantity of carbides are crucial to the razor blade edge;

Carbides can be improved through optimization of rolling and annealing.